fishing Dartmouth sea angling Devon uk charter boat shore plaice turbot bass river dart |

TACKLE TIPS - REASSEMBLING CLUTCH

WASHERS |

|

In order to function correctly, the metal and fibre clutch washers must be reassembled in the correct order. But before you do this, it is a good idea to lightly smear the cogs on the outside edge of the main gear clutch housing with a trace of high quality grease. Waterproof grease, such as that used on "Outboard" engines on boats is the very best, as it does not absorb moisture in the salty, condensation clad atmosphere which pervades the inside of most fishing reels.

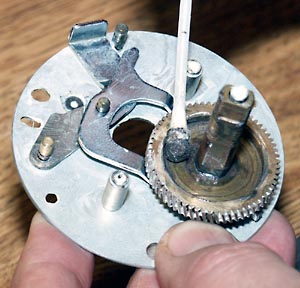

Next, use a cotton bud to lightly smear "Copperlube" or similar grease which is made for use on the brake shoe components in motor vehicles, around the inner base of the main gear clutch housing.

"Copper Lube" grease contains fine particles of copper which lubricate while preventing slippage or seizing of components under friction. It is readily available in a small tube from most motoring D.I.Y. stores and garages. You can also buy brake grease in small sachets from motor cycle shops, which contains traces of Titanium and performs the same function. This is also fine for our intended purpose. I often place the main clutch housing temporarily on the gear shaft on the main housing base plate while I carry out these jobs, although I know I will have to lift it off again when it is complete to fit other components which go underneath it on the main housing base plate. This is just a convenient way of holding the clutch housing temporarily while you are working on its reassembly and lubrication.

Now to reinsert the various washers in their correct sequence into the clutch housing gear. If you used my earlier wire threading tip, they will be in the correct order, which starting from the bottom and working up is: 1. Fibre friction washer. 2. Plain flat metal washer without any protruding lugs. 3. Fibre friction washer. 4. Plain flat metal washer with two protruding lugs - these lugs locate in the slots which are machined on the inside face of the perimeter of the clutch housing gear. Their purpose is to prevent this middle metal pressure washer from rotating within the housing. 5. Fibre friction washer. 6. Plain flat metal washer. This top one may on some makes of reel have a raised ridge surrounding the central hole. If it has, this ridge should be facing uppermost. The step at 4 above is crucial. The middle disk which is prevented from rotating by the lugs, dictates how the remaining clutch components function. You also might like to replace the inner liner of the handle needle roller bearing on top of these washers at this stage if it came out when you disassembled the reel. You may prefer to do that task later during the reassembly of the completely serviced reel. Now that was pretty straightforward wasn't it. (c) Paul Bright - Reel Value - 9th January 2004 |